Calculating heat losses resulting from thermal bridges is one of the only ways to improve SAP calculations without the need to re-design any aspect of the building, making the price per carbon of this process very low. This is because SAP punishes the lack of calculations by assuming very high values for the thermal bridging heat loss. So, to ensure that a well-designed building fabric is accounted for in the SAP calculations, undertaking bespoke thermal bridging calculations for key building junctions is recommended. Even if the calculations are performed for only a handful of key junctions, the savings can be so significant that this can be the difference between whether or not a building meets the energy requirements. In London residential builds, these savings are also essential to meet the 10% improvement over Part L regulations required in the new London Plan.

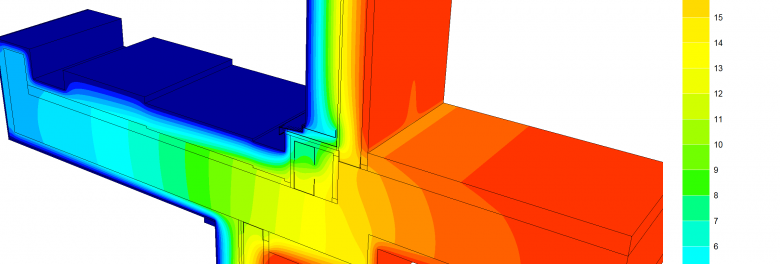

Another benefit from bespoke thermal bridge calculations is the identification of potential cold spots that can lead to condensation and mould growth. This is a glaring problem that affects a third of UK’s households, hazardous to the health of occupants and with potential to denigrate the appearance of the home. In new builds that have to comply with airtightness standards, any reduction in ventilation can lead to moisture buildup which will exacerbate the condensation if cold spots occur.

The correct management of thermal bridges during the design and construction stages can bring benefits not only for compliance, but also to ensure the production of high quality homes.

Posted on March 4th, 2020

Author: Rodrigo Guedes

Related services: SAP (Domestic), Air Tightness Testing, Thermal Bridging Analysis, Condensation & Moisture Management,